Introduction

AI (Artificial Intelligence) and IoT (Internet of Things) have proven to be incredibly helpful technologies, transforming industries and offering numerous benefits. These technologies work hand in hand to collect, analyze, and leverage data to drive intelligent decision-making and optimize processes.

By integrating AI and IoT, businesses can achieve enhanced efficiency, improved productivity, and a range of other advantages. AI algorithms enable data-driven insights, empowering businesses to make informed decisions and devise effective strategies. IoT devices, equipped with sensors, gather real-time data from connected devices, machines, and environments. AI then analyzes this data, providing valuable insights for optimizing operations, predicting maintenance needs, and improving overall performance.

Moreover, AI and IoT enable personalized customer experiences, proactive support, and innovative services, fostering customer satisfaction and loyalty. Energy efficiency, supply chain optimization, enhanced safety and security, advancements in healthcare, and the potential for innovation are further ways in which AI and IoT prove their usefulness.

AI- Artificial Intelligence

Artificial Intelligence (AI) refers to computer systems or machines that can perform tasks that would typically require human intelligence. It involves teaching machines to think and learn like humans, enabling them to understand, reason, and make decisions.

AI can be categorized into two types: narrow AI and general AI. Narrow AI is designed for specific tasks, such as voice assistants, image recognition, or recommendation systems. General AI, on the other hand, would have the ability to understand and perform any intellectual task that a human can do.

AI relies on algorithms, which are sets of instructions that tell machines how to solve problems or complete tasks. These algorithms use data to learn and improve over time. The more data an AI system has, the smarter and more accurate it becomes.

Artificial Intelligence has a wide range of applications across various industries. Healthcare and Medicine, Finance and Banking, Retail and E-commerce, Manufacturing and Production, Transportation and Logistics, Energy and Utilities, Education and E-learning, Media and Entertainment, Automotive and Autonomous Vehicles, Agriculture and Farming, Customer Service and Support, Cybersecurity and Fraud Detection, Gaming and Virtual Reality, Natural Language Processing and Translation and many more.

Overall, AI is about creating intelligent machines that can understand, learn, and make decisions, ultimately helping to solve complex problems and make our lives easier.

IoT – Internet of Things

IoT, or the Internet of Things, refers to the network of physical devices embedded with sensors, software, and connectivity that enables them to exchange data and interact with each other over the internet.

These devices, often referred to as “smart” devices or “things,” can range from everyday objects like household appliances and wearable devices to complex industrial machinery and infrastructure.

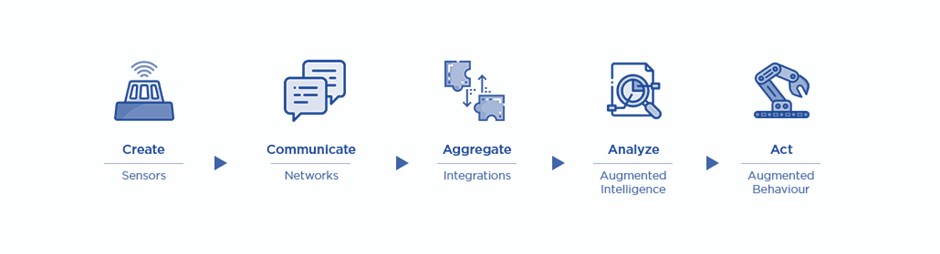

IoT devices are equipped with sensors that gather information from their surroundings. This data can include environmental conditions, such as temperature, humidity, and light intensity, as well as user interactions, machine performance, and energy consumption. The devices then transmit this data to a centralized system or the cloud, where it can be processed, analyzed, and acted upon.

The applications of IoT are vast and span across various domains, including home automation, healthcare, transportation, agriculture, manufacturing, and smart cities. For example, in home automation, IoT enables the control and monitoring of household devices remotely, optimizing energy usage and enhancing convenience.

Growth of AI and IoT in recent years

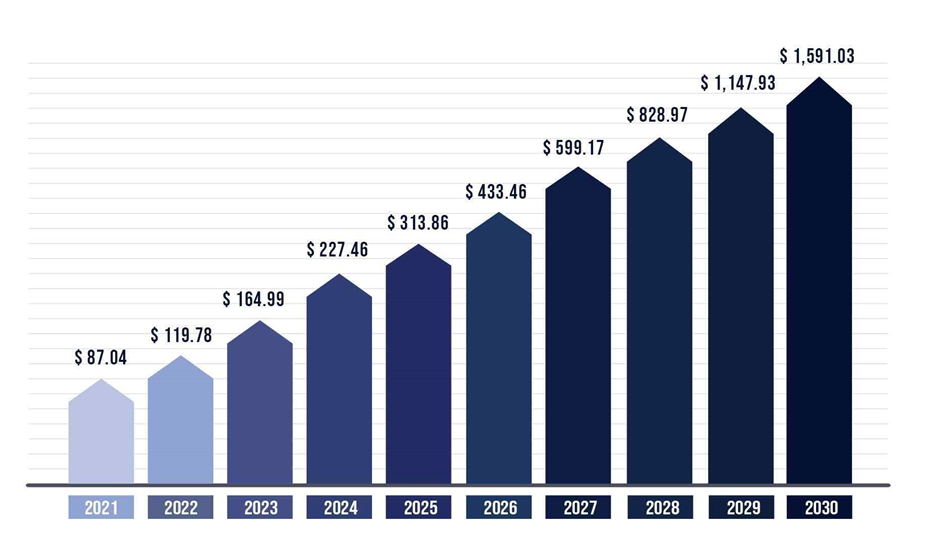

The growth of Artificial Intelligence (AI) and the Internet of Things (IoT) over the next five years is expected to be significant, with both technologies poised to have a profound impact on various industries and everyday life.

- AI is projected to continue expanding its presence across industries, with advancements in machine learning, deep learning, and natural language processing.

- The integration of AI into various applications, such as autonomous vehicles, healthcare diagnostics, and personalized services, will become more prevalent. AI-driven automation and intelligent decision-making will lead to increased efficiency, productivity, and innovation.

- Similarly, the IoT will experience substantial growth as more devices become connected and communicate with each other. The number of IoT devices is expected to skyrocket, resulting in an unprecedented level of connectivity and data generation.

- This will lead to enhanced smart home automation, optimizing industrial processes, improved asset tracking, and efficient supply chain management.

- Additionally, the IoT will contribute to the development of smart cities, where interconnected systems and sensors enable better resource management, traffic optimization, and enhanced public services.

Furthermore, the convergence of AI and IoT will create powerful synergies. AI algorithms will be deployed on IoT devices, enabling real-time data analysis, predictive maintenance, and autonomous decision-making at the edge. This fusion will unlock new possibilities, such as intelligent monitoring systems, smart energy management, and personalized user experiences.

In upcoming next five years, we can anticipate exponential growth in AI and IoT, driving transformative changes in industries, society, and the way we interact with technology.

Overall, the integration of AI and IoT holds vast possibilities for fostering positive advancements and establishing a world that is increasingly interconnected, intelligent, and streamlined. This convergence has the potential to accelerate growth in various domains, one of the major area is factory automation, propelling them towards further development in the years to come.

Factory Automation

Factory automation refers to the use of technology and machinery to automate manufacturing processes and tasks traditionally performed by humans.

It involves the integration of various technologies, such as robotics, sensors, control systems, and software, to streamline production, increase efficiency, and improve quality.

The goal of factory automation is to minimize manual labour, reduce errors, increase productivity, and enhance overall operational performance. By automating repetitive and mundane tasks, human workers can focus on more complex and value-added activities, leading to improved job satisfaction and skill utilization.

There are several key components and concepts associated with factory automation:

Robotic Systems

- Robots play a significant role in factory automation. They can perform tasks with precision, speed, and consistency. Industrial robots are used for assembly, welding, material handling, and other manufacturing processes.

- They can be programmed and equipped with sensors to adapt to changing conditions and work alongside human operators.

Control Systems

- Factory automation relies on control systems that monitor and regulate the operation of machines and processes.

- These systems include programmable logic controllers (PLCs) and distributed control systems (DCS) that manage and coordinate the flow of materials, control machine movements, and ensure synchronization in the production line.

Sensors and Feedback Devices

- Sensors are essential components in factory automation as they collect data from the environment and machines.

- They provide real-time feedback on parameters such as temperature, pressure, position, and velocity. This data is used to monitor machine performance, detect anomalies, and enable closed-loop control systems.

Internet of Things (IoT)

- The integration of IoT technologies in factory automation enables the connectivity and communication of devices, machines, and systems.

- IoT devices and sensors collect data and transmit it over the internet, facilitating real-time monitoring, data analytics, and remote control of manufacturing processes.

Data Analytics and Artificial Intelligence

- Factory automation generates vast amounts of data. Data analytics and AI techniques are used to analyze this data, identify patterns, optimize production parameters, and predict equipment failures.

- AI algorithms can optimize production schedules, predict maintenance needs, and make data-driven decisions to improve efficiency and reduce downtime.

Flexible Manufacturing Systems

- Factory automation aims to create flexible manufacturing systems that can adapt to changing product requirements and market demands. Flexible automation allows for quick changeovers, modular production, and customization, enabling manufacturers to respond rapidly to customer needs and reduce time-to-market.

The benefits of factory automation include increased productivity, improved product quality, reduced costs, enhanced worker safety, shorter production cycles, and the ability to scale operations efficiently. It also enables manufacturers to stay competitive in a rapidly changing global market.

Role of AI and IoT in factory automation

AI (Artificial Intelligence) and IoT (Internet of Things) are two transformative technologies that play a crucial role in factory automation. When combined, they enable smarter, more efficient, and interconnected manufacturing processes.

Data Collection and Connectivity

IoT devices, such as sensors and actuators, collect real-time data from various sources within the factory environment. These devices are connected to the internet, forming a network of interconnected devices. The data collected includes machine performance, environmental conditions, energy consumption, and more.

Data Analytics and Machine Learning

AI algorithms analyze the massive amount of data generated by IoT devices. Through advanced analytics and machine learning techniques, patterns, anomalies, and insights are extracted from the data. AI algorithms can learn from historical data to predict machine failures, optimize production processes, and make data-driven decisions.

Predictive Maintenance

By leveraging AI and IoT, factories can implement predictive maintenance strategies. Sensors collect data on machine performance, and AI algorithms analyze this data to identify patterns that indicate potential equipment failures. By detecting issues in advance, maintenance can be scheduled proactively, reducing downtime and improving overall efficiency.

Real-time Monitoring and Control

IoT devices and AI systems enable real-time monitoring of machines and processes. Factory operators can remotely monitor machine status, receive alerts for abnormal conditions, and make adjustments as needed. AI algorithms can provide recommendations for optimizing production parameters, ensuring consistent quality and efficiency.

Autonomous Systems

AI and IoT enable the development of autonomous systems in factory automation. For example, autonomous robots can navigate the factory floor, perform tasks, and communicate with other machines using IoT connectivity. AI algorithms allow these robots to learn and adapt to dynamic environments, improving efficiency and flexibility.

Energy Management

IoT devices and AI algorithms can optimize energy consumption in factories. Real-time data on energy usage is collected and analyzed, allowing AI systems to identify opportunities for energy conservation and efficiency improvements. This leads to cost savings and reduced environmental impact.

Supply Chain Optimization

AI and IoT enable better integration and coordination along the supply chain. Through real-time data sharing and analytics, manufacturers can optimize inventory levels, track shipments, and streamline logistics processes. This improves overall supply chain visibility, reduces costs, and enhances customer satisfaction.

Real Life examples of AI and IoT

Wearables like smart glasses to view instructions hands-free and perform real-time situation awareness.

Continuous monitoring of equipment performance, energy use, environment temperature, and the presence of toxic gases for better workplace safety

Smart lighting and HVAC control for efficient energy consumption.

Industrial analytics using data from edge devices on the production floor.

AI-enabled software can help create several optimized designs for a single product. The software, also known as generative design software, requires engineers to provide certain input parameters such as: Raw materials, Size and weight, Manufacturing methods, Cost and other resource constraints.

Using these parameters, the algorithm can generate various design permutations.

The software lets engineers can test various designs against a wide range of manufacturing scenarios and conditions to pick the best possible outcome. The carmaker Nissan is using AI to develop never-seen-before car designs in the blink of an eye. The process would take human designers’ months, or even years to complete.

Conclusion

In summary, the combination of AI and IoT in factory automation brings numerous benefits, including enhanced data collection, predictive maintenance, real-time monitoring, autonomous systems, energy management, and supply chain optimization. Together, these technologies drive efficiency, productivity, and competitiveness in modern manufacturing environments.

In summary, the combination of AI and IoT in factory automation brings numerous benefits, including enhanced data collection, predictive maintenance, real-time monitoring, autonomous systems, energy management, and supply chain optimization. Together, these technologies drive efficiency, productivity, and competitiveness in modern manufacturing environments.

Your article helped me a lot, is there any more related content? Thanks!