Introduction

With the increasing environmental concern over the usage of petroleum-based energy, electrical energy is the main focus across the globe as it is a cleaner form of energy. Hence, the industry has gradually started moving towards cleaner energy-driven applications such as electric vehicles, smartphones, laptops, etc.

An electric vehicle runs on the electric power delivered by a battery pack. Electric vehicles come with large battery packs, owing it’s relatively poor energy density. There are various types of batteries that can be used for this purpose like lead-acid, Li-ion, NiMH, etc. Among the existing batteries, Li-ion batteries are the most

efficient and are competitive enough to make electric vehicles feasible.

But with the Li-ion batteries being volatile and hazardous, comes another problem: Battery Management.

A battery management system (BMS) for Li-ion batteries is an electronic system that manages a rechargeable battery system that is highly sensitive and has the potential to explode if incorrectly designed.

Battery management is essential as it helps to protect the connected load from improper operations such as over-current, under-voltage, over-voltage, etc. It is also essential to monitor the thermal aspects of the cells.

Modifying the charging cycles to maximize battery life and minimize deterioration is one way to improve battery efficiency, lifespan, and usage patterns. There are several ways to integrate AI into battery management systems for optimal battery management performance. Artificial Intelligence (AI) has emerged as a transformative tool for optimizing battery lifecycle management, offering innovative solutions to enhance battery efficiency, predict failures, and extend lifespan. This article explores how AI is being utilized in Li-ion battery lifecycle management.

Basics and Key

A battery management system (BMS) is an electronic system that monitors and regulates the parameters of a battery, such as voltage, current, temperature,

and state of charge. It consists of sensors, controllers, and communication interfaces. The BMS collects data from various sensors to accurately assess the

battery’s condition and performance. This data is then processed by algorithms that anticipate potential obstacles and make decisions to optimize battery

operation.

AI algorithms mostly concentrate on battery health and performance. The condition and charge of the batteries are evaluated for battery management.

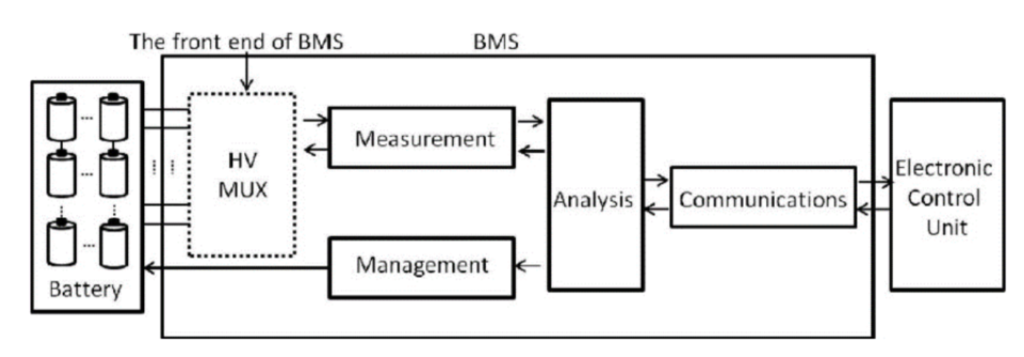

Battery Management Systems (BMS) can be designed using Centralized, Modular, or Distributed architectures.

- Centralized Architecture: Features a master controller responsible for functions like cell monitoring, battery safety operations, cell balancing, thermal control, and SoC estimation. However, its complexity increases with battery capacity.

- Modular/Distributed Architecture: Addresses the complexity of centralized systems, making it suitable for larger battery packs.

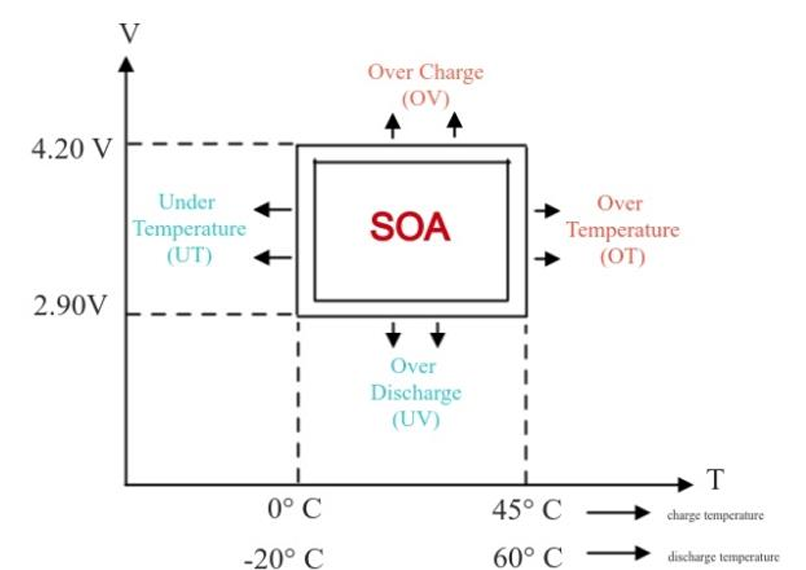

Safe Operating Area (SOA)

SOA ensures the battery’s voltage, current, and temperature remain within permissible limits. Deviations such as over/under-voltage or temperature are identified and managed by the BMS, which monitors individual cells and acts as an interface between input and output systems.

State of Charge (SoC)

SoC indicates the available battery capacity, expressed as a percentage of its rated capacity.

Cell Balancing

Cell balancing equalizes cell voltages and SoC in a battery pack, extending its life and improving safety. It mitigates stress caused by cell over/under-voltage, reduces hazards, and ensures optimal energy utilization while maintaining battery health.

The term “state of health” (SOH) refers to the overall state and ability of the battery to function as intended over an extended period. To identify trends in temperature swings, charge-discharge cycles, and consumption patterns. The phrase “state of charge” (SOC) describes how detecting degradation or possible problems may lead to proactive maintenance and an extended battery life. The term “state of charge” (SOC) describes how much energy is available in a battery at any one time based on its remaining capacity. They facilitate a more sustainable and circular economy, optimize energy use, and lower expenses. The field of energy storage might be completely changed by battery management systems driven by AI and ML.

How AI Enhances Battery Management Systems

A battery-management system (BMS) detects unusual circumstances and validates the proper method for controlling the temperature behaviour of the battery to avoid any negative impact on the power-intake profile.

The BMS is responsible for monitoring the SOC, SOH, SOP, and the remaining useful life (RUL) of the battery pack as well as for cell balancing, thermal management, and safety.

While AI technology would improve and transform the implementation of LIBs for EV applications, the deployment of AI/ML algorithms into real-world scenarios for predicting and discovering battery materials and estimating the state of the battery system is challenging

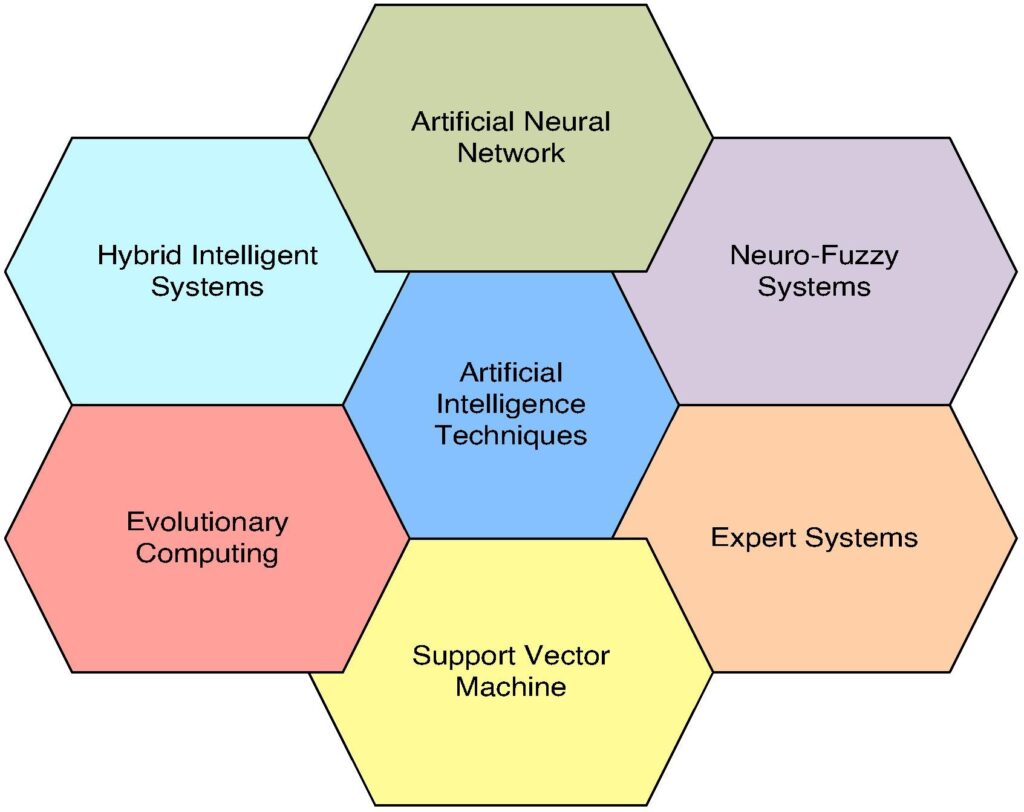

BMSs are currently installed with a fixed control algorithm, without adjustments or modifications during the system’s lifetime. However, the batteries have a relatively long life span, with many warranties ranging from 5 to 10 years. The operational environment may vary during the system’s lifespan due to such a long period. These changes may need adjustments to the control technique to improve performance characteristics. The significance of SOH and SOC for the BMS extends beyond the accuracy of its calculations. A BMS is responsible for not only communicating data about the batteries to the user, but also for protecting the battery. The estimates of SOH and SOC, particularly in Li-ion batteries, influence the instructions provided to the battery. Below shows the different AI techniques that can be used for state estimation.

AI and other sciences have led to transformations in many fields, including energy storage and management being it one. This is a major step in the application of AI to BMS data using various algorithms. The idea is to address the inefficiencies caused by overly complex modern solutions for energy storage

Different approaches for Li ion Battery Management Systems

1. LSTM-based deep learning approach for the RUL prediction of batteries.

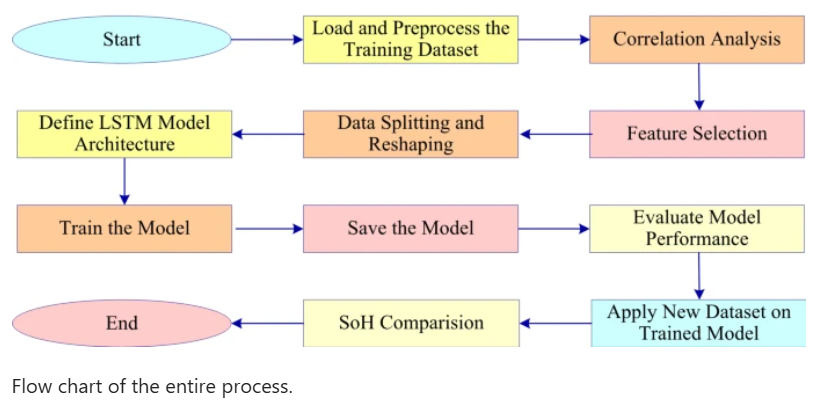

an LSTM-based deep learning model using Keras predicts the Remaining Useful Life (RUL) of Li-ion batteries, enabling predictive maintenance for Battery Management Systems (BMS). It utilizes Dataset 05 from the NASA library, which features a constant-voltage-constant-current charging profile. The battery’s initial capacity is 1.86 Ah, gradually decreasing to 73% over time.

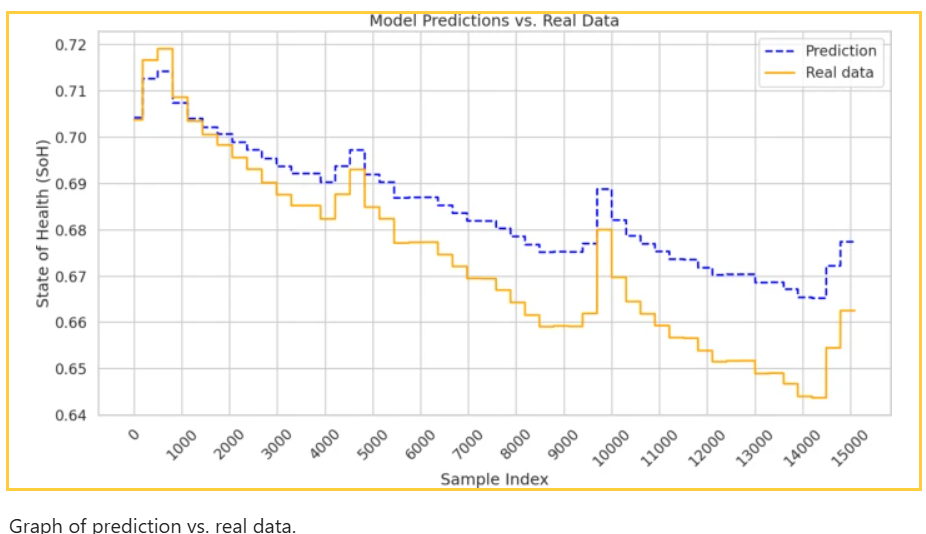

The data preprocessing stage includes feature selection and correlation analysis, followed by a 70-30 train-test split. The model is built using Keras’ sequential API, featuring a 16-unit LSTM layer and a dense regression output layer. The model undergoes training for 60 epochs and is evaluated using metrics like MAE, RMSE, and MAPE. The trained model is saved as JSON and H5 files for reuse.

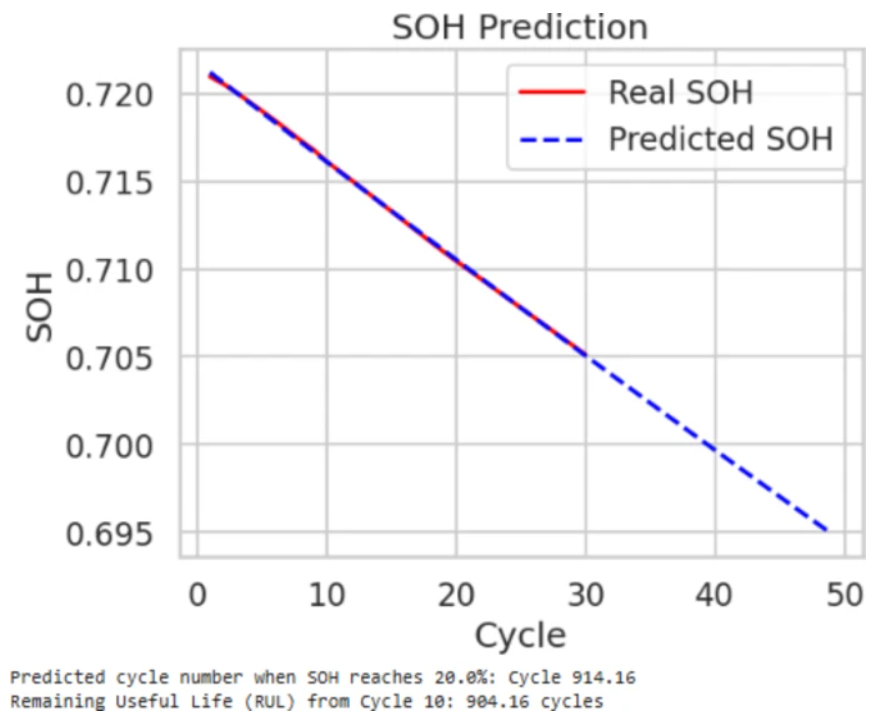

When tested on real-time IoT data, the model achieves an RMSE of 0.01173 and accurately tracks trends in the State of Health (SoH) of the battery. Predictions indicate that the battery reaches a critical SoH threshold of 20% around Cycle 914, assisting in maintenance scheduling. Visualizations show close alignment between real and predicted SoH values, demonstrating the model’s effectiveness in forecasting battery health and extending its lifecycle.

2. State of Charge (SoC) estimation using a machine learning-based artificial neural network (ANN)

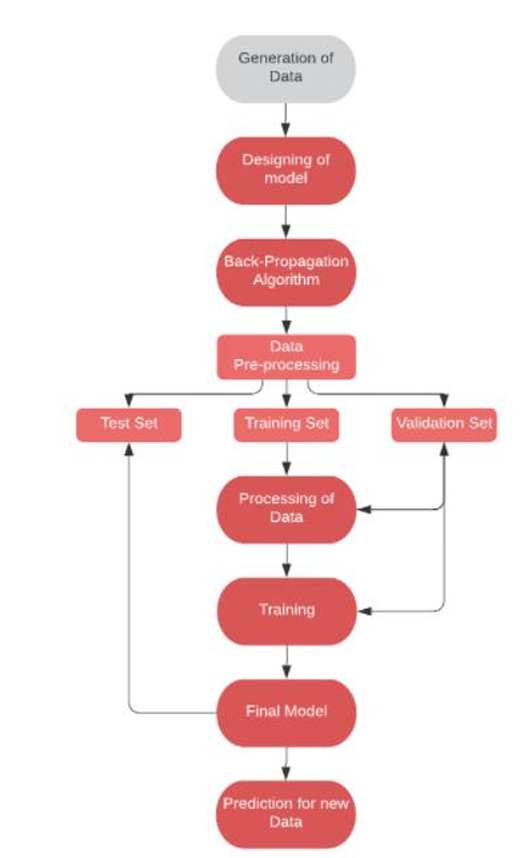

This method uses backpropagation algorithm for training. This method combines data-driven techniques and neural network modeling to estimate the SoC of Li-ion cells accurately.

State of Charge (SoC) is a critical parameter for evaluating battery performance, estimating operational range (e.g., in electric vehicles), and ensuring safe cell operation. However, due to the complex chemical reactions and nonlinear battery characteristics, SoC cannot be directly measured; it must be calculated. Accurate SoC estimation methods include:

- Coulomb Counting

- Open Circuit Voltage (OCV)

- Kalman Filter

- Neural Networks

- Fuzzy Logic

- Hybrid Methods

Artificial Neural Networks (ANN) are particularly effective due to their ability to handle non-linearities but require extensive training, validation, and testing data for accuracy.

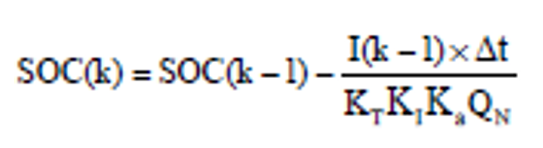

To calculate the SoC of a battery:

Detailed Process Overview:

- Data Generation and Simulation:

Data was collected from various 18650 Li-ion cells, such as those from LG and Panasonic, to understand the variation of the State of Charge (SoC) with respect to voltage and temperature. Due to constraints like COVID-19, simulated data for the BAK H18650CQ cell was used. The simulation parameters included discharge capacity variation with temperature (KT), capacity variation with the discharge rate (KI), and an ageing factor (Ka) accounting for capacity degradation over time. Input variables for the model included current (I), discharging time (t), and maximum charge capacity (QN). - ANN Training, Validation, and Testing:

The backpropagation algorithm was selected for training the Artificial Neural Network (ANN). Input data was split into training, validation, and test datasets. The ANN architecture consisted of three input neurons representing voltage, current, and temperature, followed by two hidden layers with 200 neurons each using Rectified Linear Unit (ReLU) activation to prevent gradient vanishing. The output layer had a single neuron activated by the Sigmoid function to keep the SoC output between 0 and 1. The model was optimized using the Adam optimizer with a learning rate of 0.0001, β1 of 0.9, β2 of 0.999, and AMSGrad set to False. Mean Squared Error (MSE) was used as the loss function, and Mean Absolute Percentage Error (MAPE) was used as a metric. The model achieved a MAPE of 0.4709%, translating to an accuracy of 99.4055%, with a loss in the order of 10⁻⁵, ensuring negligible inaccuracies. - Communication and Data Interfacing:

Sensor data was transferred from Arduino to Raspberry Pi using a handshaking algorithm through USB communication at a baud rate of 19200. Initially, Arduino waits for a signal from Raspberry Pi to start the process. Once initiated, Arduino collects sensor data and sends it iteratively to Raspberry Pi, acknowledging each data type (voltage, current, etc.) before moving to the next. This process ensures continuous monitoring, safe operation, and reliable SoC calculation. - Cloud Connectivity and Dashboard Visualization:

Processed data from Raspberry Pi was sent to the cloud using a time-series database (InfluxDB), which required Wi-Fi connectivity for real-time updates. The data was temporarily stored for analysis and integrated into a Grafana dashboard. The dashboard provided real-time metrics such as voltage, current, temperature, SoC, and charging status. It also offered graphical trend analysis and error detection, enabling quick corrective actions and remote monitoring capabilities.

3. Neuro-Fuzzy Logic Systems (FLS) for Battery SoC and SOH Estimation

Fuzzy Logic Systems (FLSs) alone have historically been insufficient for accurately estimating the State of Charge (SoC) and State of Health (SoH) of battery packs. While there has been limited use of FLSs in this domain, researchers have increasingly shifted toward combining FLSs with neural networks to create Neuro-Fuzzy Logic Systems (NFLS). This integration leverages the strengths of both approaches: the adaptive, learning capabilities of neural networks and the linguistic, rule-based reasoning of fuzzy logic. The neuro-fuzzy approach addresses limitations such as the need for extensive experimental datasets required by neural networks and the static nature of traditional fuzzy logic solutions. It enables dynamic and real-time system adaptation, making it well-suited for Battery Management Systems (BMS).

The Adaptive Neuro-Fuzzy Inference System (ANFIS) framework, commonly used in NFLS, incorporates Sugeno fuzzy rules and has a five-layer structure. The first layer consists of input variables, which represent data such as voltage, current, and temperature. The second layer, the membership layer, applies fuzzy membership functions to these input values, generating membership weights. Layer three, the rule layer, activates rules based on the fuzzy memberships, computing the degree of rule activation. The fourth layer, the defuzzification layer, processes these activations to extract output values. Finally, the fifth layer consolidates the results into a crisp output value, providing interpretable results such as SoC and SoH.

The primary advantage of NFLS lies in its ability to modify fuzzy system parameters using a learning mechanism with input-output training data. This adaptability allows the system to function effectively even in scenarios where datasets for deep neural network training are unavailable. Real-time data acquisition during system deployment compensates for the lack of pre-existing datasets. Although the performance of neuro-fuzzy systems is generally expected to surpass that of neural networks alone, the field lacks extensive studies to provide quantifiable comparisons. Future research is anticipated to focus on addressing the scarcity of implementations and exploring the system’s potential for more robust and accurate battery management.

4. Support Vector Machine (SVM) for Battery SoC and SoH Estimation

Support Vector Machine (SVM) is a powerful supervised learning algorithm that has been increasingly utilized for State of Charge (SoC) and State of Health (SoH) estimation in batteries. SVM-based techniques provide a structured and efficient approach to model complex relationships in battery systems by leveraging the principles of statistical learning. Unlike traditional neural networks, which rely on empirical risk minimization and may face issues with local minima, SVMs use structural risk minimization, solving a quadratic programming problem to find a global optimum. This ensures better generalization and potentially superior performance in certain scenarios.

SoC Estimation with SVM

In early studies, the SoC of a battery was estimated using SVM by modeling it as a function of key parameters such as voltage and current. Subsequent studies expanded this input set to include additional variables such as temperature, voltage, and current measurements, which were used to train the SVM model. By incorporating a broader set of inputs, these methods captured the nonlinear dependencies between SoC and battery parameters more effectively, resulting in more accurate estimations. This approach demonstrated advantages over conventional neural network methods, particularly in terms of stability and generalization.

SoH Estimation with SVM

For SoH estimation, a two-step approach involving SVM training and virtual testing was applied using battery data collected under realistic Electric Vehicle (EV) current profiles. In the first step, an SVM model was trained with current, temperature, and SoC as inputs and voltage as the output. This model effectively served as a voltage look-up table for any given set of hypothetical input conditions based on real-world battery profiles. The virtual testing approach involved applying the SVM-derived model to generate voltage responses for specific current, temperature, and SoC inputs, mimicking standard performance testing scenarios.

The results of the virtual tests were then analyzed to compute key SoH metrics, such as internal resistance and battery capacity. These metrics are critical for evaluating the performance and longevity of the battery. By relying on SVM for both training and simulation, the approach avoided the need for extensive real-world testing, significantly reducing the time and resources required for SoH estimation.

Advantages and Limitations

SVMs offer distinct advantages over traditional neural networks for battery parameter estimation. Their reliance on global optimization ensures robustness and avoids pitfalls such as overfitting and local minima, which can affect neural networks. Additionally, the use of kernel functions allows SVMs to capture complex nonlinear relationships effectively. However, SVMs do not completely replace Artificial Neural Networks (ANNs) or other machine learning models. For instance, multilayer perceptrons (MLPs) can still compete with SVMs in terms of accuracy and computational efficiency, particularly for datasets with specific characteristics.

5. Expert Systems (ES) for Fault Diagnosis and Energy Management

Expert systems (ES) are specialized computer programs designed to emulate human decision-making by using a structured repository of knowledge and reasoning mechanisms. These systems are composed of several key components: a feature data repository, a knowledge base, an explanation machine, a reasoning machine, a knowledge acquisition mechanism, and a human-machine interaction interface. Together, these components enable the system to analyze complex data and provide actionable insights or decisions.

Feature Data Repository and Knowledge Base

The feature data repository serves as a database containing extracted fault symptom information in a unified form. This structured data is critical for building a robust system capable of diagnosing and resolving issues. The knowledge base, on the other hand, houses expert-level information and rules derived from domain knowledge. It is designed to address specific scenarios, such as identifying faults or managing energy systems effectively.

Reasoning and Explanation Mechanisms

The reasoning machine interprets the information within the knowledge base to draw conclusions or recommend actions. This process is further supported by the explanation machine, which provides transparency by detailing the reasoning process, allowing operators to understand the rationale behind system decisions. Such transparency fosters trust and aids in decision-making during critical operations.

Knowledge Acquisition and Human-Machine Interface

The knowledge acquisition mechanism is responsible for updating and refining the knowledge base by incorporating new data, either automatically or via human input. The human-machine interaction interface ensures that operators can communicate seamlessly with the expert system, enabling them to provide inputs, request analyses, or execute commands based on the system’s outputs.

Application in Energy Management Systems

In the context of energy management, expert systems are instrumental in executing regular state estimations and security analyses. These tasks are typically performed at fixed intervals but can also be triggered by specific switching actions or operator requests. The system’s logic can evaluate changes in load levels, compare current conditions with previous states, and initiate appropriate actions based on the situation. For example, if a switching action alters the network configuration, the expert system can direct the state estimator to reassess the network’s status, ensuring accurate real-time monitoring.

Processing Analog Data for Enhanced Decision-Making

Expert systems excel at processing vast volumes of analog data from transmission systems. Using numeric-intensive algorithms, these systems analyze raw analog measurement data, identify anomalies, and remove false readings. The state estimator, an integral part of the system, refines this data further, delivering accurate estimations for all network quantities. This processed information is far more useful to operators than raw data, enabling them to make informed decisions regarding network operations and fault management.

6. Evolutionary Algorithm (EA) in Battery Management Systems (BMS)

Evolutionary Algorithms (EAs) are powerful computational tools inspired by the principles of natural evolution. They are increasingly being adopted to address complex challenges in Battery Management Systems (BMS) for electric vehicles (EVs), such as capacity modeling, enclosure design, and system optimization. EAs are particularly well-suited for problems involving non-convex optimization, multi-objective criteria, and complex design requirements.

Key Motivations for Using EAs in BMS

EAs offer several advantages over traditional optimization methods:

- Gradient Independence: Unlike derivative-based or gradient-dependent optimization methods, EAs do not rely on gradient information, making them applicable to problems with discontinuities or non-differentiable objectives.

- Non-Convex Problem Solving: EAs excel in addressing non-convex optimization problems, which often have multiple local optima, ensuring a higher likelihood of finding global or near-global solutions.

- Multi-Objective Optimization: EAs are inherently flexible and can efficiently balance competing objectives, such as performance, cost, and safety, in multi-objective scenarios.

Structure and Process of EAs

EAs are iterative, population-based algorithms that simulate evolutionary processes. The steps involved in a typical EA include:

- Initialization: The algorithm begins by generating a random population of candidate solutions. Each individual in the population represents a potential solution encoded as a set of parameters or genes.

- Reproduction: New candidate solutions are generated from the current population using genetic operators such as crossover (combining features of two or more solutions) and mutation (introducing random variations). These operations promote diversity and explore new regions of the solution space.

- Fitness Evaluation: Each candidate solution is evaluated against a predefined fitness function that quantifies its quality or suitability for the given problem. This function may include factors like capacity retention, thermal performance, or safety metrics in BMS applications.

- Selection: The fittest individuals are selected to propagate to the next generation, ensuring that high-quality solutions have a higher likelihood of contributing to future populations. Selection strategies often use techniques like tournament selection or roulette wheel selection to balance exploration and exploitation.

- Iteration and Convergence: The algorithm iterates through multiple generations, refining the population by iteratively applying reproduction, fitness evaluation, and selection. The process continues until specific stopping criteria, such as a maximum number of iterations or a satisfactory fitness level, are met.

Conclusion

Artificial Intelligence is revolutionizing Li-ion battery lifecycle management by providing tools for design optimization, real-time monitoring, predictive maintenance, and efficient recycling. Battery management systems provide the ability to maximize energy use in charging, discharging, and other processes. These devices can forecast battery health using AI algorithms, maximizing deterioration and prolonging longevity. AI-enabled real-time monitoring helps quickly identify abnormalities or possible breakdowns, preventing dangerous scenarios and improving dependability.Furthermore, AI-powered systems enable flexible energy storage plans that better integrate renewable energy sources by balancing supply and demand for energy.

Through continual improvement enabled by the iterative learning process of machine learning, algorithms are refined based on continuing data streams, resulting in more accurate forecasts and more intelligent energy use.

As industries increasingly rely on battery-powered solutions, AI-driven innovations will be crucial in meeting performance, safety, and environmental goals. Harnessing the power of AI not only ensures the longevity of batteries but also contributes to the broader objective of a sustainable and energy-efficient future.

Looking for an In-depth Understanding of Li Ion Battery Technology, Preparation, Machinaries , Financials, Operations, Marketing Models?

Enquire Today : https://pragyatmika.co.in/li-ion-battery-assembly-plant/

Looking to learn Li Ion Battery Electronics, Li Ion Battery Analysis and Modelling, Implementation of AI & ML in Li Ion Battery BMS, Design of Li Ion BMS,

Enquire Today : https://pragyatmika.co.in/battery-electronics-bms-design/

Do you have Design Requirements of Li Ion Battery, Design of Battery BMS and Other EV Electronics Subsystems and Components, Implementing IoT and AI for Battery Fleet and Distribution Pack?

Enquire Today : https://pragyatmika.co.in/post-your-qury/